Proud to show you what we're made of…

When you get a Smoker Craft, you can be sure you're getting a boat that carries the pride of our family name, using the finest materials, state-of-the-art equipment and quality workmanship. From hull design and construction down to the last factory-installed feature, we continually strive for best-in-class to give you a boat you and your family will take pride in for years to come.

Transom

The transom board is made of 1.5" pressure-treated plywood which is covered by our Limited Lifetime Warranty. The board is sandwiched between the aluminum transom and a second aluminum sheet and anchored using stainless steel bolts.

Side Panels

The side panels are strengthened by rolling lap strakes into the aluminum, adding rigidity to the sides that prevent the "oil can" appearance of many other boats.

Performance Hull System (PHS)

Our exclusive Performance Hull System is a completely customizable trim tab feature that increases speed, reduces pounding, eliminates porpoising, and provides improved efficiency with less fuel consumption and engine laboring. The system allows you to tune your hull to maximize performance, depending on the weight and horsepower of your engine. Additional benefits include improved visibility, reduced wake size, better handling, and less hull stress.

Hydra-lift Reverse Chine Hull

Our exclusive high-performance hull provides superior lift to get you out of the hole and on plane quickly. The reverse chine design keeps the bow down during acceleration, provides sports-car-style turning agility and offers exceptional stability both while running at high speeds and while at rest.

Spray Rails

Spray rails are rolled into the side panels, giving a much cleaner appearance and eliminating the line-breaking rough edges found on many other boats. The combination of spray rails with the Hydra-Lift reverse chine design delivers the driest ride in the industry.

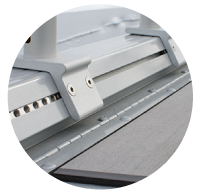

IGTS (Integrated Gunnel Track System)

The exclusive new IGTS Integrated Gunnel Track system is an innovative gunnel design that allows for easier installation of rod holders, downriggers and other accessories. See page 4 to learn more about this exciting new feature. Only available on Pro Mag and Explorer Series boats.

The exclusive new IGTS Integrated Gunnel Track system is an innovative gunnel design that allows for easier installation of rod holders, downriggers and other accessories. See page 4 to learn more about this exciting new feature. Only available on Pro Mag and Explorer Series boats.

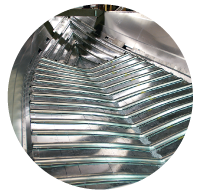

Twice-Baked Paint Finish

Smoker Craft boats are sprayed with 3 coats of base urethane paint and baked in a large oven for 20 minutes at 180 degrees. The hull is then masked off and the boat enters the accent stripe paint booth where it is sprayed with 3 coats of accent color. The boat then runs through a bank of infrared heating coils, giving it a twice-baked, diamond-hard finish that is resistant to chipping and fading and will look great for years to come.

5-Keel Construction

While many manufacturers have stopped adding keels, we continue to use up to 5 keels on our hulls to provide longitudinal strength and protect the bottom when beaching or trailering. In addition, the keels help the boat plane quickly by breaking the water during acceleration. They also improve tracking and help hold position while fishing.

One-Piece Bottom

The Hydra-Lift Hull begins with a one-piece bottom, unlike many other manufacturers. Aluminum gauge ranges from .100" to .125".

Gas Tank Integration

We place the gas tanks below the floor toward the center of the boat between the floor stringers to centralize the weight of the fuel. This gives the boat a softer ride and helps keep the bow down.

Nex Gen Hulls

Smoker Craft’s next-generation hulls (on select Pro Angler and Ultima models) feature a longitudinal stringer system for internal support, instead of cross ribs. The stringer system is welded together in a jig to ensure proper alignment and is riveted to the hull bottom to create a uniform hull structure.

AIRS

The Hydra-Lift Hull is supported by Smoker Craft’s exclusive Advanced Integrated Rib System (AIRS). This integrates heavy machine-formed hat-shaped ribs in the bow with cross ribs on 10" centers on the bottom. The bow ribs conform to the contour of the bow and angle toward the cross ribs to add strength to the critical area of the hull when the boat is running. Floor stringers are fastened to the cross ribs to support the floor panels and enhance hull strength.

Construction You Can Count On.

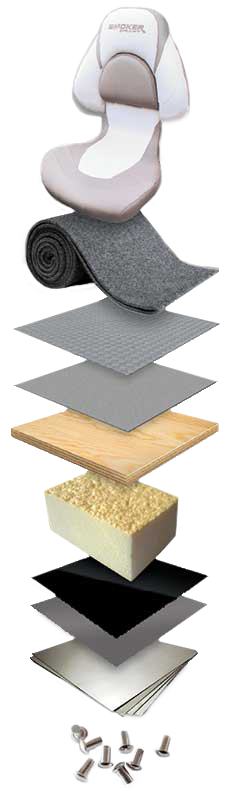

UPHOLSTERY

UPHOLSTERY

Produced in-house for quality control and customization, Smoker Craft upholstery is precision cut and installed using only stainless, non-corrosive fasteners. Cushioning foam is biocide treated to help prevent mildew and fungal growth that can discolor vinyl. This process is a key differentiator when comparing Smoker Craft to other manufacturers.

CARPET & VINYL

Smoker Craft casting platforms and decks are covered in marine-grade carpet that is both glued and stapled, while cockpits feature easy-to-clean carpet that is both glued and stapled, while cockpits feature easy-to-clean vinyl. Optional snap-in carpet can be added over the vinyl for added comfort.

eVA SOFT TOUCH TRACTION MATS

Easy to clean. Mold, mildew and stain-resistant. Superior wet or dry traction.

FLOOR PANELS

Our pressure-treated plywood is 5.8" in the cockpit and 3//4" or the casting decks. They carry a lifetime warranty and will not warp or rot.

INJECTED FOAM FLOTATION

Unlike other manufacturers, we inject foam flotation into pre-routed holes in the floor panels to fill the entire cavity under the floor. The adhesive property of our foam allows it to bond to both the floor panels and the hull providing enhanced support and excellent sound dampening.

TWICE-BAKED PAINT FINISH

The Smoker Craft paint method includes 3 coats of base urethane and 3 coats of the accent color, then baking under infrared hearing coils after each step–giving it a twice-baked, diamond-hard finish that is resistant to chipping and fading, looking great for years to come.

ZINC CHROMATE PRIMER

Zinc Chromate primer is chemically etched into the aluminum hull, forming a corrosion-resistant surface. This also creates an even, bondable surface for the final paint layer.

HIGH-GRADE ALUMINUM

Smoker Craft boats start with 5032 h34 Cold-Rolled Aluminum for its superior strength, hardness, and corrosion resistance. Computerized fabrication equipment delivers precision components and ensures consistent quality.

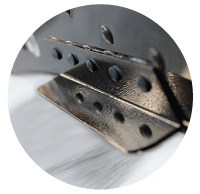

DOUBLE RIVETS

The sides and transom are riveted with a double row of airplane-style rivets on the seams on all models 17' and above. The rows are offset to completely seal the seam.